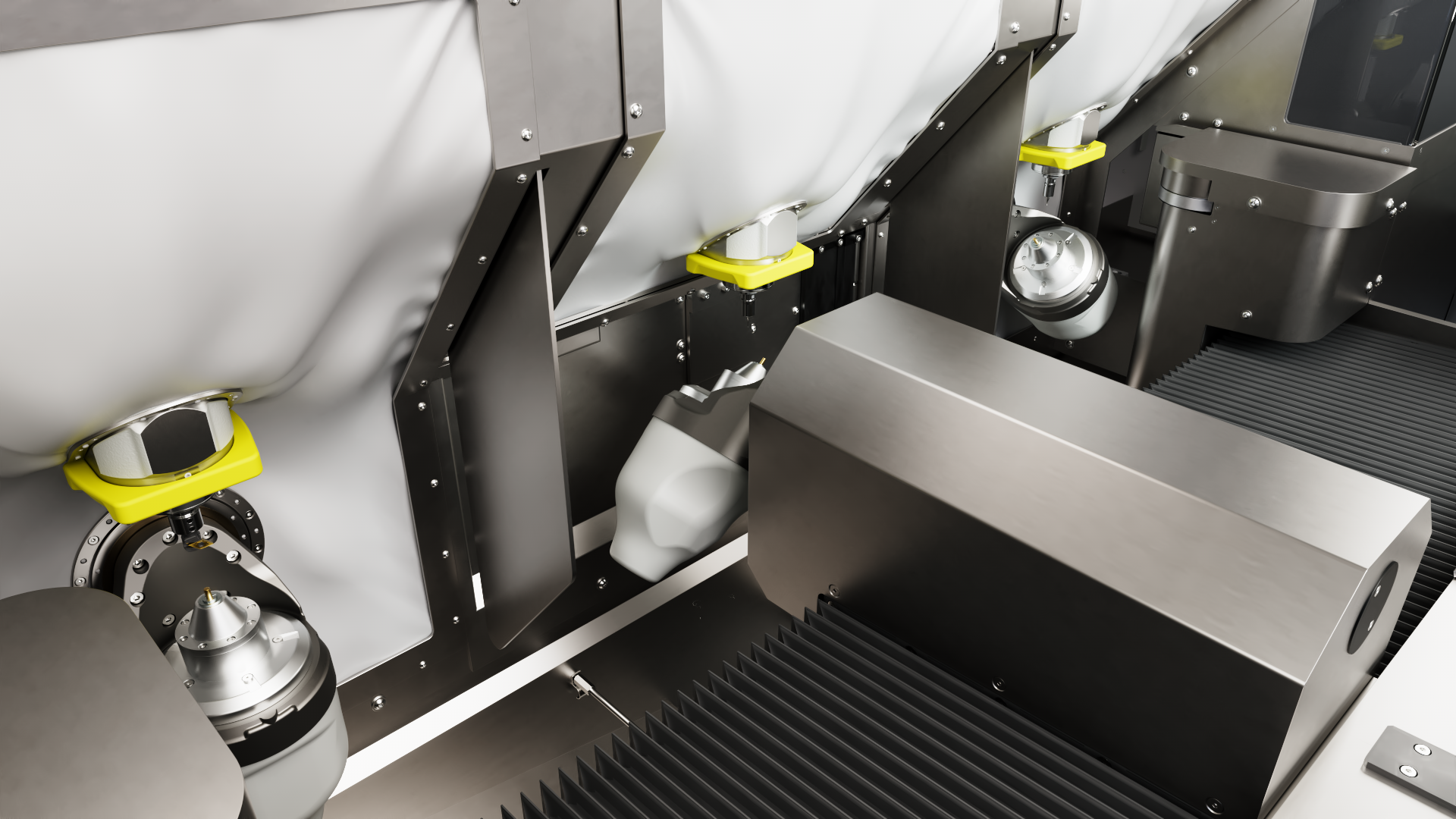

K5-TRIO

5-axis multistation

The K5-TRIO multistation 5-axis machining center is part of an innovative concept that involves having production equipment that is scaled to the parts to be manufactured. The precision and rigidity of this compact machine come from extremely short force loops and limited moving masses. The three stations enable a finished part to be obtained at the machine output in a short machining time, as operations and counter-operations are performed in parallel.

- Massive machine frame ensuring high machine stability.

- High-speed machining with 2.5G axis acceleration.

- Machining from micro bars up to Ø10 mm or blanks.

- Automatic 50-position tool changer and intermediate buffer with 4 positions (3 on the center station).

- Reduced footprint and energy consumption.

C-AXIS & MICRO BAR

The new generation of C axes developed by our teams offers improved technical characteristics. This C axis can be used both in positioning mode for 5-axis milling operations and in spindle mode for turning operations with a maximum rotation speed of 5,000 rpm. The C-axis accepts different types of workpiece clamping. Either a micro bar system with collet clamping for micro bars up to Ø10 mm (0.39 inches) and up to 165 mm (6.5 inches) long, or an automatic zero point system allowing the adaptation of specific fixtures. The new external geometry and the axis cover improve sealing and prevent chip accumulation. A multi-way rotary joint supplies compressed air or vacuum, offering the possibility of having a large number of functions directly on the workpiece fixture.

Controlled unloading of parts with station sorting to facilitate adjustment and parts output dedicated to SPC control.

- Technical characteristics

-

K5-TRIO Type HSC milling and turning Number of axis 5 Machinable volume 50 x 50 x 40 mm (1.96 x 1.96 x 1.57 in) Axis travel X/Y/Z 78 / 56 / 50 mm ( 3.07 / 2.20 / 1.96 in) Axis feedrate X/Y/Z 30'000 mm/min (1181 ipm) Axis acceleration X/Y/Z 25 m/s² (82 ft/s²) Rotary Axis B +/- 108° ; 250 rpm Rotary Axis C 360° ; 5'000 rpm Tool changer 50 positions per station ; 4-positions intermediate buffer

(3 positions on central station)Electrospindle With sleeve ; HSK-EZ15 indexable ; 60’000 rpm ; closed-loop control ; mechanical brake Loading Manual or automatic ; workpiece, blanks or micro-bars Areas of application Watchmaking, electronics, medical, energy, etc. Controller / HMI Beckhoff Cooling and mist extraction Fully integrated system ; 3 level filtering Power supply 3x400V PE+N, 50 Hz, 16A Pneumatic supply >5.5 bar ; <450 l/min (>80 psi ; <15.9 scfm) ; quality classes 4/5 Cold water supply <18°C ; 15 l/min ( <64.4°F ; 3.9 gal/m) Overall dimensions 1'980 x 1'800 x 1’942 mm ( 78 x 71 x 76.5 in) / 4'000 kg (8818 lbs) Options and accessories Optical tool break detection

Wireless 3D measuring probe

Automatic fire extinguishing system

Automated loading and unloading system - Downloads