Kummer K50

High precision, high precision, high productivity compact turning center

The machine

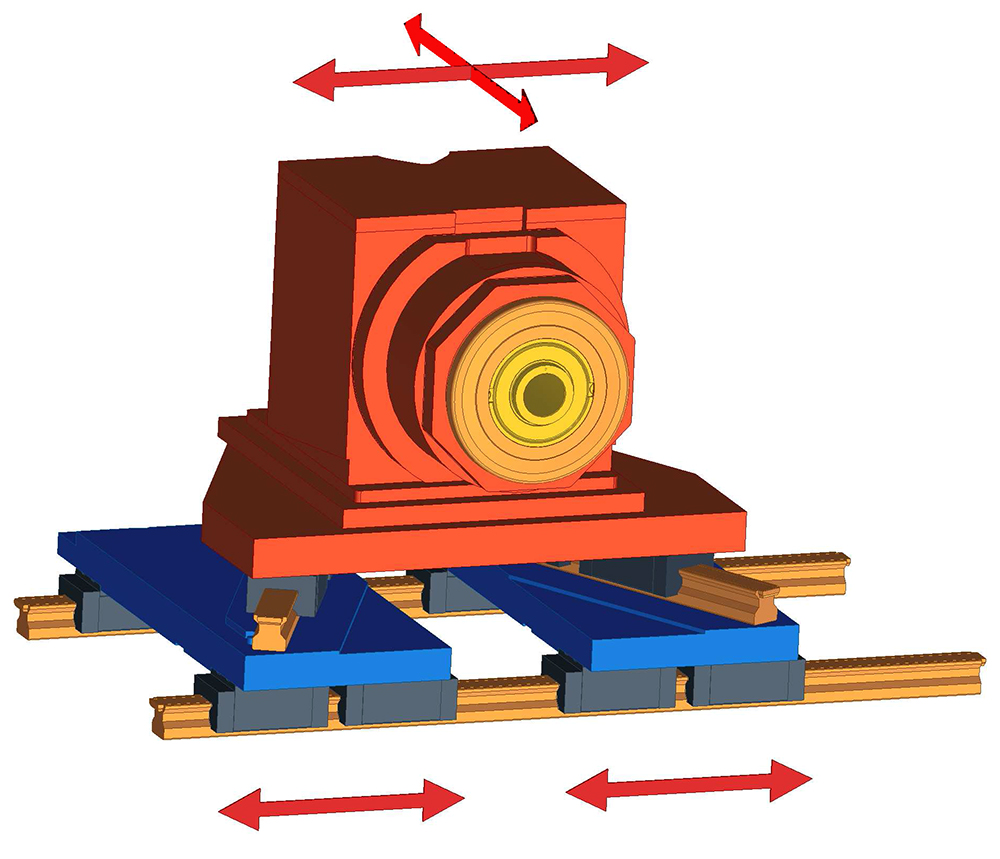

The turning center Kummer K50 has been designed to fully release the accuracy, speed and acceleration potential of linear motors. The LINEAR SLIDES KINEMATICS LSK concept similar to well proven K250 enables up to 10 m/s² accelerations for repositioning accuracy.

Steel frame monobloc main base filled with water based concrete resting on 3 support pads with no need for foundation ties, optimally designed for cutting fluid and chip evacuation through its center to the back.

- Unproductive time reduced by over 50%.

- Integrated and thermally stabilized linear motors.

- Direct measurement of the slide movements by two absolute optical glass scales (resolution 0,01 µm).

- No residual faults from the ball screws.

The Spindle

Several mobile direct drive spindles are available, according to the requirements of the specific machining solution. The speed range goes from 8’000 rpm to 20’000 rpm. The spindle can be equipped with steel or ceramic precision ball bearings or hydrostatic bearings.

- 技术特征

-

K50 Type Single spindel turning machine Guideways High precision central-lubricated preloaded roller bearings Drives Linear motors Acceleration 10 m/s² Rapids up top 50 m/min Slides motion measuring Direct reading on optical scale. Water and chip exclusion guaranteed by air flow. Measurement resolution 0,01 μm Workheads Direct drive ball bearings

From 8'000 to 20'000 rpmNumerical control Siemens 840Dsl Floor space 1'280 x 800 mm (without cooling unit) Weight Approx. 1’800 kg Options and accessories Pneumatic side autoloader